Get detailed information and offers.

Fill out the form completely and send it; Let us inform you in detail about our company and our products.

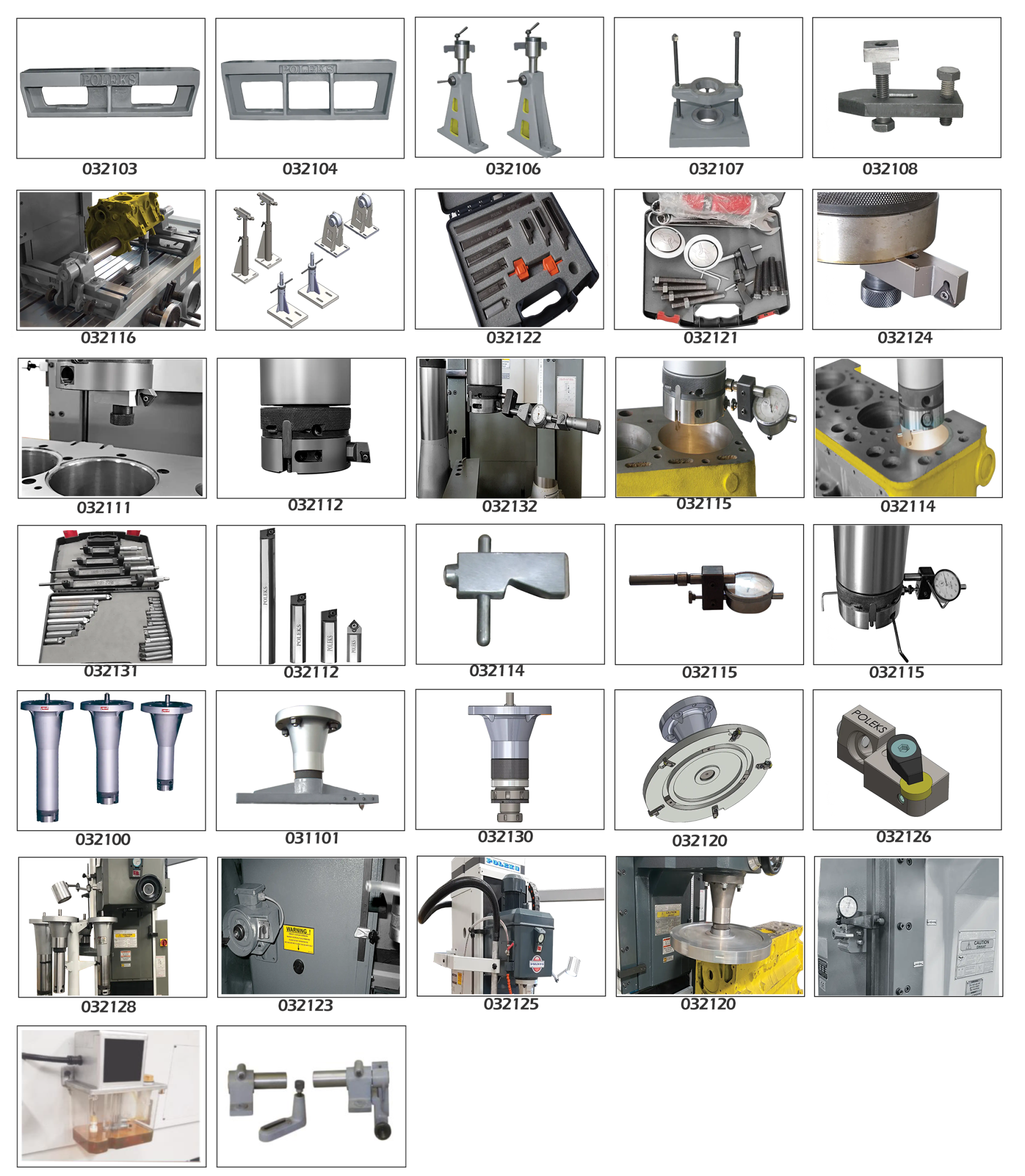

| Serial No | Standard / Extra Equipments | Standard | Extra |

| 032100 | Boring head | 3 | |

| 032101 | Surfacing head | 1 | |

| 032103 | Pair of parallels, supports 100 mm (small) | 2 | |

| 032104 | Pair of parallels, supports 200 mm (big) | 2 | |

| 032106 | Pair of quick setting up fixture | Extra | |

| 032107 | Setting-up fixture for finned engine blocks | 1 | |

| 032108 | Clamping engine block | 4 | |

| 032109 | Setting screws and nuts | 10 | |

| 032110 | Automatic lubrication system | 2 | |

| 032111 | Chamfering tool | 3 | |

| 032112 | Chip breaker | 5 | |

| 032113 | Surface Milling Chip breaker | 1 | |

| 032114 | Cylinder centering device | 1 | |

| 032115 | Tools setting device without dial gauge 1 | 1 | |

| 032116 | Universal Fulcrum lever and V block apparatus(Type 2) | 1 | |

| 032117 | Boring heads changer robot | Extra | |

| 032119 | Mliilng head safeguard | Extra | |

| 032120 | Circular multiple surface milling head | Extra | |

| 032121 | Tool Box ( 2pcs wrench - oil pump -assembly tools screws and nuts ) | 1 | |

| 032122 | Tool Box for chip breakers and tool holders | 1 | |

| 032123 | Diamond(tool) dresser ( to sharpen the chip braker ) | Extra | |

| 032124 | Boring tool component with a dead-end hole tool | Extra | |

| 032125 | Movable shavings vacum device | Extra | |

| 032126 | Tool Holder (for Cbn/Pcd) | Extra | |

| 032127 | V-type engine fixing apparatus(Type 1) | Extra | |

| 032128 | Heavy-Duty V-type engine apparatus(Type 3) | Extra | |

| 032129 | Special heavy-duty boring head | Extra | |

| 032130 | Special boring head for suitable morse system | Extra | |

| 032131 | Micrometer type tooling system | Extra | |

| 032132 | Feed dial guage micrometer | Extra |

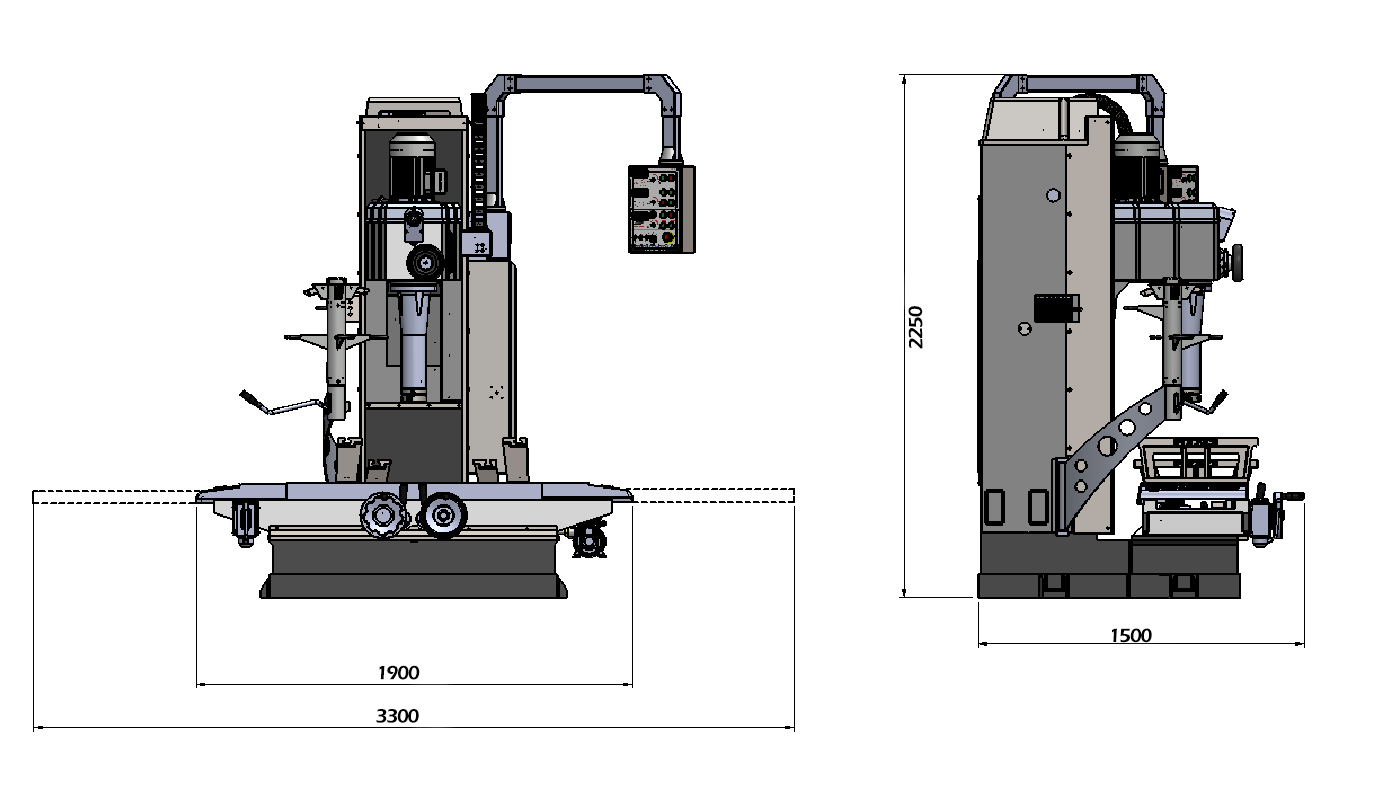

| Texchnical Specidications | RM 200 | |

| Max.Boring diameter | mm | 200 |

| Min.Boring diameter | mm | 35 |

| Max milling width | mm | 400 |

| Distance between spindle centerline to column | mm | 400 |

| Max.Boring stroke(without boring head) | mm | 1180 |

| Table working surface | mm | 1100x460 |

| Max.Longitudinal travel of table | mm | 1200 |

| Max table cross traverse | mm | 100 |

| Spindle rotation speeds (speed adjustable) | d/(Rpm)Min | 0-700 |

| Spindle head fine feed speed | d/(Rpm)Min | 0-700 |

| Spindle head fast feed,up and down (speed adjustable) | d/(Rpm)Min | 1400 |

| Table quick feed speed | mm/min | 10000 |

| Table automatıc fine feed speeds ( speed adjustable) | mm/sec | 0-700 |

| Electric system | V | 380 - 24 |

| Spindle motor | Kw | 2.2 |

| Spindle head traverse,up and down motor | Kw | 1 |

| Table automatic feed motor | Kw | 1,5 |

| Work length of machine | mm | 3000 |

| Length of machine | mm | 1900 |

| Width of machine | mm | 1500 |

| Height of machine | mm | 2250 |

| Weight of machine | kg | 2500 |