Get detailed information and offers.

Fill out the form completely and send it; Let us inform you in detail about our company and our products.

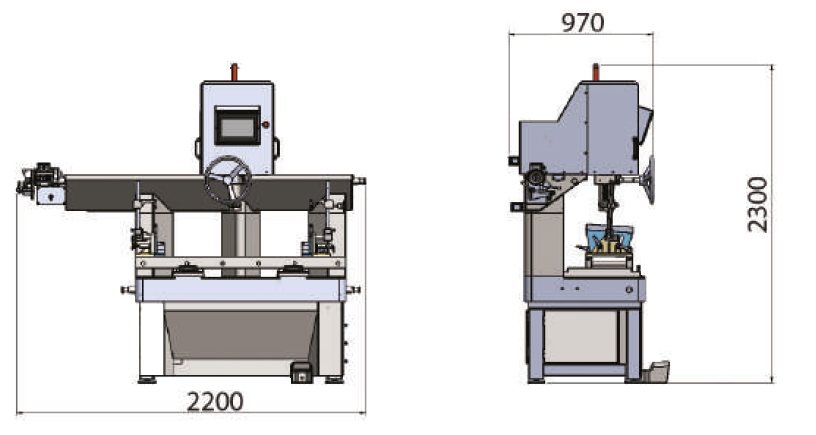

Valve Seat and Guide Machine

| Standard Equipments | Piece |

| Set Single Axis Roll-Over Fixture | 1 |

| CARBIDE BIT SHARPENER (withing grinding wheel Ø 100 | 1 |

| VACUUM TESTING SYSTEM | 1 |

| Ø50 mm. PAD WITH FOAM FOR VACUUM TESTER | 1 |

| Ø70 mm. PAD WITH FOAM FOR VACUUM TESTER | 1 |

| 50x80 mm. PADS WITH FOAM FOR VACUUM TESTER | 1 |

| 70x80 mm. PADS WITH FOAM FOR VACUUM TESTER | 1 |

| TOOL SETTING DEVICE | 1 |

| BUBBLE LEVEL FOR PILOT DIA. SHANK Ø 9.52 mm | 1 |

| TORX T8 SCREW DRIVER | 1 |

| ALLEN KEY T 3 mm | 1 |

| ALLEN KEY T 2.5 mm | 1 |

| VALVE SEAT ANGLE CONTROL DEVICE | 1 |

| TOOL HOLDERS | 1 |

| TOOL HOLDER | 1 |

| BIT HOLDER (PLK-OL/16-30)-(PLK-0/16-30)-(PLK-1/28-42)-(PLK-2/40-58) | 1 |

| Cutting Bits | Piece |

| 3 ANGLE CUTTING CARBIDE BIT(30ºx1.5mm)-(30ºx2.0mm)-(45ºx1.5mm)-(45ºx2.0mm)-(45ºx2.5mm)-(30ºx2.5 mm)-(45ºx1.3mm) | 1 |

| 90 DEGREE FLAT CUTTING BIT | 1 |

| DEGREE SINGLE ANGLE CUTTING BIT (20-30-45) | 1 |

| Paralel Supports | Piece |

| (50x30 x240mm) Rabbet parallel support | 2 |

| (50x30x240mm) Flat parallel support | 2 |

| (40x20x310mm) Flat parallel support | 2 |

| (50x60x350mm) Cast-iron head clench support | 2 |

| Portable quick-pratic clench apparatus | 2 |

| Carbide Pilot Miller | Piece |

| Carbide Pilot(Ø9,52-L:165mm)4,98mm-5,00mm-5,48mm-5,50mm-5,98mm-6,00mm-6,98mm7,00mm-7,98mm-8,00mm | 10 |

| Tapered Steel Ø4,98 mm - 12.00mm | Piece |

| Tapered Steel(Ø9,52-L:165mm)4,98mm-5,00mm-5,48mm-5,50mm-5,98mm-6,00mm-6,01mm6,98mm-7,00mm-7,01mm-7,98mm-8,00mm-8,01mm-8,25mm-8,50mm-8,98mm-9,00mm9,50mm-10,00mm-11,00mm-11,98mm-12,00mm | 22 |

| Extra Equipments | Piece |

| Extra Vacum Tester Pads (different sizes) | Extra |

| Diamond (for tool grinding apparatus) | Extra |

| Parallel Supports | Extra |

| Tool Holders | Piece |

| Tool Holder (PLKT 158)-(PLKT 4090)-(45100)-(70120) | Extra |

| Bit Holders | Piece |

| Bit Holder (PLK 4090-1)-(PLK4090-2)-(PLK 45100-1)-(PLK 45100-2)-(PLK 45120-1) | Extra |

| Cutting Bits | Piece |

| 3 Angle Cutting Carbide Bit (different degree selection) | Extra |

| Carbide Pilots | Piece |

| Carbide Pilot(Ø9,52-L:165mm),(6,01mm,7,01mm,8,01mm,8,25mm,8,50mm,8,98mm,9,00mm) | Extra |

| Tapered Steel Pilots | Piece |

| Tapered Steel(Ø9,52-L:190mm)-(7,00mm-7,01mm-7,02mm-7,95mm-7,96mm-7,97mm-7,98mm-7,99mm8,00mm-8,01mm-8,02mm-8,03mm-8,05mm-8,25mm-8,45mm-8,97mm-8,98mm-7,99mm-8,99mm9,00mm-9,02mm-9,48mm-9,49mm-9,50mm-9,51mm-10,00mm-10,98mm-11,00mm-11,98mm-12,00mm | Extra |

| TECHNICAL SPECIFICATIONS | KR 1600 | |

| Max.Boring capacity ( with standard tools) | dia | 70 |

| Max.Boring capacity ( with extra tools) | dia | 120 |

| Min.Boring capacity | dia | 16 |

| Max. Table traverse travel (forward-backward movement) | mm | 260+130 |

| Max.Cylinder head placing capacity (Length) | mm | unlimeted |

| Max.Cylinder head placing capacity (Width) | mm | 600 |

| Max.Cylinder head placing capacity (Height) | mm | 520 |

| Workhead travel -Lengthwise (standard) | mm | 1150 |

| Workhead travel -Lengthwise (with parking area) | mm | 1440 |

| Workhead travel Sphere-cylinder travel | mm | 30 |

| Max. spindle inclination | degree | 15 |

| Spindle travel (down-up) | mm | 190 |

| Spindle motor power (servo motor with servo reducer) | kw | 0.75 |

| Spindle rotation speed | r.p.m | 0-500 |

| Electric System | V | 380-24-3Phase |

| Pneumatic supply | bar | 6 |

| Max. air flow | l/mn -CFM | 400/15 |

| Noise level at 500 RPM | Dba | 40 |

| Work Lenght of Machine | mm | 2200 |

| Lenght of machine | mm | 2200 |

| Width of machine | mm | 970 |

| Height of machine | mm | 2300 |

| Weight of mahcine | kg | 1700 |